Small Shelf

There is a corner in the half bath that needs a shelf as there is no medicine cabinet in this very small room. I designed this shelf considering the space, materials on hand and the appearance I was after. Being such a small room, anything that is not rectilinear and has rounded lines that the eye will follow will work. The Lyptus and Bloodwood make an interesting wood combination. Their contrast is strong. In its unfinished state, Lyptus has delicate salmon overtones. Unfortunately, no matter what finish is used, these light subtle colors are lost and the wood turns a darker brown. The Bloodwood's deep red color makes me drool. I think this wood is simply beautiful. I prepared the surfaces with 100, 120, 150, 180, 220, 320, 400, 600, 800 and 1000 grit sandpaper. The resulting polished surface on these hard woods is spectacular. I use a mask and air filtering fan when sanding. I know that if you can smell the wood you are actually consuming it. Woods like Poplar and Aspen smell bad. Sassafras is caustic and makes me choke up. Alder is real nice, I use the cutoffs as woodchips in the Weber Grill. The Bloodwood smells real sweet and is very interesting. The sawdust from the Bloodwood that landed on my face around the mask caused my skin to stain like a red rash that went away in a day or so. Wood is a carcinogen. Use caution and always wear a respirator-dust mask when making sawdust.

CLICK ON A PICTURE TO SEE FULL SIZE

:

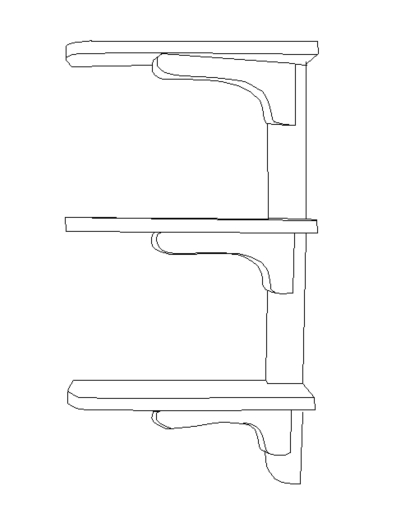

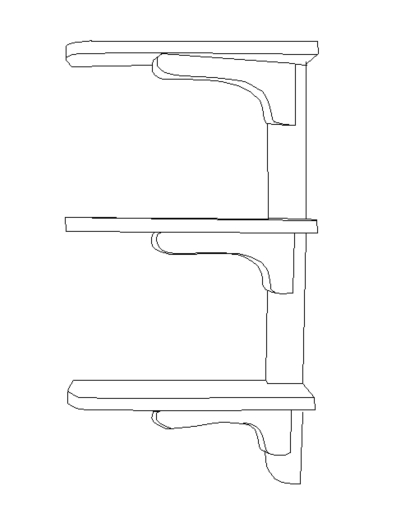

DESIGN SKETCH

:

The lumber looks like this after planing. The design drives the need for an assembly scaffold. Perfectly square boxes were built to clamp the parts together to for drilling and assembly. I made MDF templates for all the parts to cut them with a router bit with a bearing. The first time I tried this on the Bloodwood it shattered like glass. So, I cut everything on the bandsaw and hence the need for 100 grit sandpaper. Later when I have wood to waste, I'll develop the techniques to use the router this way to cut complex curves.

:

This is the assembled shelf prior to the finish. After the finish is applied the Lyptus will get darker.

:

To finish the wood and protect it from water, oils and cleaners an oil based semi-gloss polyurethane was used. The polyurethane is thinned with mineral spirits by about 8% to 10%. Four very thin coats were applied. Between each coat 1000 grit wet dry sandpaper was used. On the large surfaces, the polyurethane was applied with a soft cotton cloth in a ball much like shellac would be. A natural fiber brush was used around the nooks and crannies. Look at the mirror like surface on the close-up. This will work real well for the kitchen surfaces. Clean-up will be a cinch providing no place for grease to hide.

:

Remember: The more you design and build "out-of the box" the more scaffolding you will require.

:

CUTOFF PROJECT

This small piece of Bloodwood was milled with a router bit. The depression was first cut with a circle cutter (General #55) and then chiseled out. The surface was sanded to 1000 grit and a lacquer finish applied. The replica of a USGS Survey marker for Longs Peak as attached with 5 minute epoxy.

:

: